Precision Parts

-

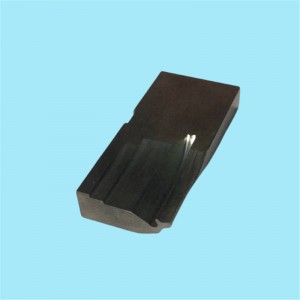

Turning Machining Metal Parts Mounting Ring

OEM Customized Universal Black Mounting Ring Bracket Housing CNC Machining Parts.

P/N: 34623-042-034-004

Material: 16MnCr5,Alloy Steel

Decription: Mounting Ring

Surface Finishing: CNC and Hardening

-

CNC Precision Machined Stainless Steel Parts

What is CNC precision machining and how does it work?

The CNC machining process uses a solid block of material such as brass, copper or steel. Using numerically controlled tools, it accurately and precisely delivers parts to a very high standard. Lathes, mills, routers, and grinders are tools typically found in CNC machinery. The digital template and autonomous machining practically eliminate human error and achieve accuracy within 1/1000th.

The CNC machine is programmed by the operator based on the specifications laid out in the CAD drawings. The programming process generates code which controls the machine to produce the desired finished product. A test run is completed to ensure that there are no errors in the programming. This trial run, called ‘cutting air’ is integral to the machining of top quality finished parts and largely eliminates material wastage and unnecessary downtime. This program can then be used repetitively to create multiple uniform products, all CNC outputs matching the prototype’s exact specifications.

Using CNC machinery is also considerably quicker than conventional machining, providing a cost-effective service with a quick turn-around.

-

CNC Custom Highly Precision Metal Parts

What is High Precision Parts?

High precision part or precision machining can always be seen when it comes to designing, manufacturing machines, components, tools and etc. So, what exactly are they, why do we need them for the manufacturing project.

High precision components or precision machining are referring to parts that have tolerances to single digit micrometers. A machine is made up of many large and small components, and if all of the parts do not have specific sizes, they cannot fit together tightly and function properly. In order for the machine to fit together tightly and have a consistent performance, machine manufacturers will find a precision part supplier that can provide them with the particular part they need.

-

CNC Custom Highly Precision Mechanical Parts

How To Draw Cnc Machined Part Drawing?

Analyze Parts And Determine Expressions

Before drawing, you must first understand the name, function of the part, its position in the machine or part, and the connection relationship of the assembly. Under the premise of clarifying the structural shape of the part, in combination with its working position and machining position, determine which one of the four types of typical parts described above (both bushings, disks, forks and boxes), and then according to Expression characteristics of similar parts, determine the appropriate expression scheme.

-

Custom Online CNC Machined Metal Parts

OEM Parts Machining Services Assuring High-Quality Customized OEM Parts

LongPan has become a trusted OEM parts CNC machining services company in China. We offer a comprehensive range of OEM Parts machining services, which helps us diverse simple to complex requirements at quick turnaround times. We can handle any project right from a raw materials sourcing to design, engineering, and prototype building. We value quality control, and regulatory compliance, which helps us assure quality to all our products. We have a vast experience in building parts for clients in defense, semiconductor, aerospace industries and more.

-

The Process of Precision CNC Parts

Applications of CNC Machining:

CNC machining is a versatile and cost-effective manufacturing process. This process is compatible with a huge range of materials. As such, CNC machining helps across a diverse array of industries for a variety of applications. Manufacturers and machinists use this process in various ways. This includes direct manufacturing process, indirect manufacturing process, or in conjunction with other processes.

As with any manufacturing process, the unique advantages of CNC machining inform the kind of applications for which it can be used. However, the benefits of CNC are desirable in virtually any industry. They are suitable for many parts and products. Since CNC machines can process almost any type of material, their applications are near limitless.

From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. Let’s get straight to it!

-

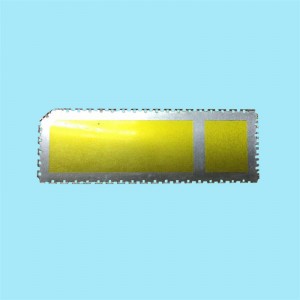

Custom CNC Precision Machined Moulding Parts

Industries That Use CNC Machining

Consumer Electronics

CNC machining also helps in the prototyping and production of consumer electronics. These electronics include laptops, smartphones, and many others. The chassis of an Apple MacBook, for example, comes from the CNC machining of extruded aluminum and then anodized.

In the electronics industry, CNC machining helps to create PCBs, housings, jigs, fixtures, and other components.

-

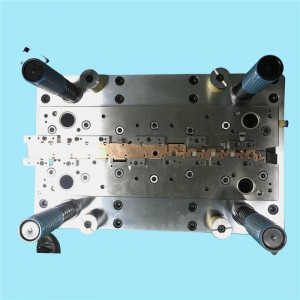

Custom Highly Precision Injection Moulding Parts

Precision mold parts performance requirements

1. Strength and toughness

High precision mold and tool components often work under harsh condition. Some usually bear a large impact load, resulting in brittle fracture. Thus, precision molds should have high strength and toughness. It’s to prevent mold components from breaking suddenly during working. And the toughness of the mold and tool mainly depends on the carbon content, grain size, and microstructure of the material.

2. Fatigue fracture performance

The fatigue fracture always happens when the high precision plastic injection mold parts are working. It’s because of the long-term effects of cyclic stress. The forms include multiple impact with small energy, stretch, contact, and bending fatigue frature. In general, this property of custom molding and tooling depends on these factors. Like its strength, toughness, hardness, and inclusions content in the material.

-

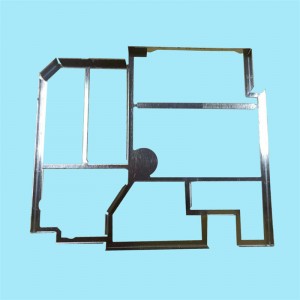

Precision Sheet Metal And Stamping Parts

Types Of Sheet Metal Stamping Processes

There are a lot of different metal stamping processes. Each of them is quite basic but as a combination, they can yield almost any geometry possible. Here are the most widespread sheet metal stamping processes.

Blanking is often the first operation to be carried out among the stamping processes. It requires a stamping press with a sharp punch. The metal sheets are usually supplied in large sizes such as 3×1,5 m. The majority of parts are not as big, so you’ll need to cut off the section of the sheet for your part, and it would be ideal to get the desired contour of the final part right here. So, blanking is applied to get the contour you need. Note that there are other ways to make a metal sheet blank such as laser cutting, plasma cutting or water jet cutting.

-

CNC Machining Materials for Stainless Steel Parts

Stainless steel is very resistant to rust and rust, making it suitable for use where parts might be revealed to the components for extensive durations. Stainless steel is additionally relatively ductile and ductile. JTR offers a variety of stainless steel alloys, consisting of food-safe ranges.

The 300 series (303, 304, and so on) are austenitic stainless steels (based upon their crystal framework) as well as are the most widely generated grades worldwide. Austenitic stainless steel grades are known for their high deterioration resistance as well as high stamina over a large temperature variety. With the exception of cool working, they are not heat treatable and also are typically non-magnetic.