Precision Sheet Metal And Stamping Parts

A Beginner’s Guide To Sheet Metal Stamping

A lot of modern products are sturdy yet very lightweight despite being made of metal. The reason for that is that the product design has been honed to such a degree that we can create even highly loaded structures from thin sheets of metal. Sheet metal stamping is one of the technologies that enable us to create the desired shape such as thin-walled objects.

What Is Metal Stamping?

Sheet metal stamping is a manufacturing process that does not subtract or add material to future parts. This method uses forming to bring straight metal sheets into the desired shape. Basically, you bend metal sheets on specialized equipment using special dies and punches. Commonly, the process does not require any heating of the sheet and thus has no heat distortion in the die surface. This fact makes the metal stamping process economical and eco-friendly as well. However, if you need a part manufactured from a thick metal sheet, the force necessary to bend it may be too large. That’s when you will need to heat the metal and refer to forging.

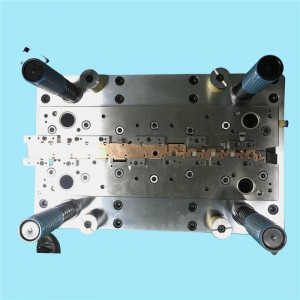

sheet metal stamping process

Bending is the basic operation to make the simplest metal stamping parts. You simply bend a metal sheet along a straight line to the required degree. In order to do that, you’ll need a stamping die with a V-shaped cavity, manufactured to the required angle and a corresponding punch.

Bending

Flanging is basically similar to bending but is done along a curved line. This makes the operation slightly more complex and special flanging equipment must be purchased.

Flanging

Embossing is very much similar to engraving but the second one cuts a small portion of the metal to create a logo or a sign on a metal part whereas embossing uses a preconfigured punch to make the indentation in the form of the required message or image.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top