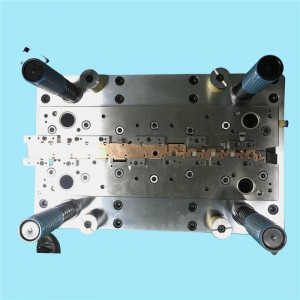

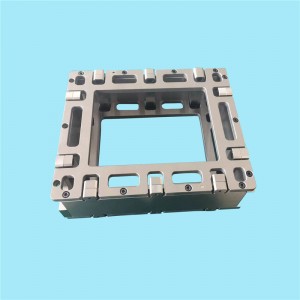

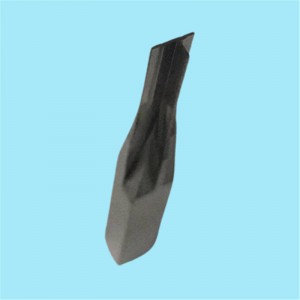

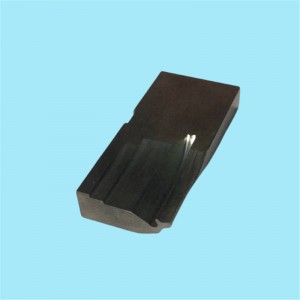

Custom Highly Precision Injection Moulding Parts

3. High-temperature performance

When the working temperature of precision molding and tooling is higher, the hardness and strength will decrease. And it results in early mold wear or failure by plastic deformation. Thus, the mold material should have high tempering stability. It can ensure that the mold has a high hardness and strength in the working temperature.

4. Resistance to cold and heat fatigue

Some molds are in the state of repeated heating and cooling in the working process. Then, it causes the surface of the cavity to be pulled and stressed, resulting in the surface crack and peel off. As a result, it increases the friction force. Beside, it prevents the plastic deformation and reduces the dimensional precision. Finally, it leads to the failure of the mold. Cold and hot fatigue is one of the primary forms of hot working tool failure.

5. Corrosion resistance

In the working process of some molds, like plastic injection molding, they produce strongly aggressive gas. Because there are chlorine, fluorine, and other elements in the plastic, they decompose and precipitate HCI and HF. They erode the cavity surface, increase the surface roughness and aggravate the wear failure.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top