CNC Machining Parts

-

Turning Machining Metal Parts Mounting Ring

OEM Customized Universal Black Mounting Ring Bracket Housing CNC Machining Parts.

P/N: 34623-042-034-004

Material: 16MnCr5,Alloy Steel

Decription: Mounting Ring

Surface Finishing: CNC and Hardening

-

OEM Customized Excellent Quality Iron Supporter

Product Name: Support

Material: 1.2767-X45 NiCrMo 4

Size: Dimensions with tolerances DIN-ISO 2768-1

Face Treatment: Black Oxide (Surface specifications according to DIN ISO 1302)

-

CNC Machined Parts based on advanced manufacturing methods

A quick comparison of CNC machine tools

CNC machines are hugely versatile pieces of equipment, in large part thanks to the range of cutting tools they can accommodate. From end mills to thread mills, there’s a tool for every operation, allowing a CNC machine to perform a variety of cuts and incisions in a workpiece.

Cutting tool materials

In order to cut through the solid workpiece, cutting tools must be made from a harder material than the workpiece material. And since CNC machining is regularly used to create parts from very hard materials, this limits the number of available cutting tool materials.

-

Solutions to Produce Complex Parts with Great Tolerances And Dimensional Parameters

Types of CNC Machining

Machining is a manufacturing term encompassing a broad range of technologies and techniques. It can be roughly defined as the process of removing material from a workpiece using power-driven machine tools to shape it into an intended design. Most metal components and parts require some form of machining during the manufacturing process. Other materials, such as plastics, rubbers, and paper goods, are also commonly fabricated through machining processes.

-

Our Materials for CNC Turning Parts

CNC Machining Process

Speaking of the numerical control machining process, it is a manufacturing process which utilizes computerized controls to operate the CNC Machines and cutting tools to get the designed parts with metals, plastics, wood or foam, etc. Although the CNC Machining process offers various operations, the fundamental principles of the process are same. The basic CNC machining process includes:

-

CNC-turned Parts with Final Inspection

METHODS OF PRECISION MACHINING

Precision machining relies on the use of advanced, computerized machine tools to achieve demanding tolerances and create complex geometric cuts with a high degree of repeatability and accuracy. This can be achieved through the use of automated computer numerical control (CNC) machine tools.

-

Highly Professional OEM CNC Machined Parts

What Is an Original Equipment Manufacturer (OEM)?

An original equipment manufacturer (OEM) traditionally is defined as a company whose goods are used as components in the products of another company, which then sells the finished item to users.

-

Custom Highly Precision CNC Machined Parts

Stainless Steel and CNC Machining

Stainless steel is an incredibly versatile metal and is often used for CNC (Computer Numerical Control) Machining and CNC turning in the aerospace, automotive and marine industries. Stainless steel is known for its corrosion resistance, and with various alloys and grades of stainless steel available, there are a wide variety of applications and use cases. This article will explain the different types of stainless steel’s mechanical properties and help you determine the best grade for your project.

-

Electroless Nickel Plating CNC Machining Parts

What are the different CNC machining processes?

CNC machining is a manufacturing process suitable for various industries, including automotive, aerospace, and construction. It can develop a wide range of products, such as car chassis, surgical equipment, and aircraft engines. The process encompasses several methods, including mechanical, chemical, electrical, and thermal, to remove the necessary material from the part to shape a custom part or product. The following are examples of the most common CNC machining operations:

-

Our CNC Milling for Various Industrial Applications

Different Types of Machining Operations

Two primary machining processes are turning and milling – descried below. Other processes sometimes are similar with these processes or are performed with independent equipment. A drill bit, for instance, may be installed on a lathe used for turning or chucked in a drill press. At one time, a distinction could be made between turning, where the part rotates, and milling, where the tool rotates. This has blurred somewhat with the advent of machining centers and turning centers that are capable of performing all the operations of the individual machines in a single machine.

-

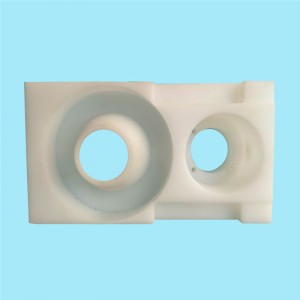

High Precision Plastic CNC Machining Parts

Which material to choose for CNC machining?

The CNC machining process is suitable for various engineering materials, including metal, plastics, and composites. The optimal material choice for CNC manufacturing depends mainly on its properties and specifications.

-

Complete Surface Finishes for CNC Milling

What Is Precision CNC Machining?

For design engineers, R&D teams, and manufacturers that depend on part sourcing, precision CNC machining allows for the creation of complex parts without additional processing. In fact, precision CNC machining often makes it possible for finished parts to be made on a single machine.

The machining process removes material and uses a wide range of cutting tools to create the final, and often highly complex, design of a part. The level of precision is enhanced through the use of computer numerical control (CNC), which is used to automate the control of the machining tools.