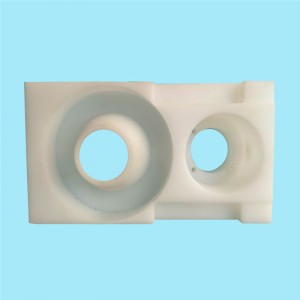

High Precision Plastic CNC Machining Parts

What are the specifics of different CNC materials?

CNC machining can produce parts from almost any metal or plastic. The properties of interest of these materials are:

1. mechanical strength: expressed by the tensile yield strength;

2. machinability: the ease of machining influences the price of CNC;

3. the cost of the material;

4. hardness: mainly for metals;

5. temperature resistance: mainly for plastics.

CNC Metals

Applications that require high strength, hardness, and thermal resistance exploit metals or, rather, metal alloys.

1. Aluminum: used to create custom metal parts and prototypes.

2. Stainless steel can be easily welded, machined, and polished.

3. Mild steel, or low-carbon steel: used for machine parts, jigs, and fixtures.

4. Alloy steel contains other alloying elements in addition to carbon to improve hardness, toughness, fatigue, and wear resistance.

5. Tool steel is advantageous for fabrication tools such as dies, stamps, and molds.

6. Brass is ideal for applications that require low friction and architecture to design gold-looking parts for aesthetic purposes.

CNC Plastics

Plastics are lightweight materials with different physical properties, often used for their chemical resistance and electrical insulation characteristics.

1. ABS: often used to manufacture prototypes before mass production by injection molding.

2. Nylon, or polyamide (PA): mainly used for technical applications because of its excellent mechanical properties, impact strength, and high resistance to chemicals and abrasion.

3. Polycarbonate is generally optically transparent, making it ideal for many applications, such as fluid devices or automotive glazing.

POM (Delrin) is the material of choice for CNC machining when parts require:

1. high precision

2. high rigidity

3. low friction

4. excellent dimensional stability at high temperatures

5. very low water absorption.

PTFE (Teflon) has resistance to operating temperatures above 200 °C and is, therefore, an outstanding electrical insulator.

High-density polyethylene (HDPE) is suitable for outdoor use and piping.

PEEK: mainly used to replace metal parts due to its high strength-to-weight ratio. Medical grades are also available, making PEEK also suitable for biomedical applications.

CNC Composite Materials

Composites, in simple terms, are multiple materials with different physical and chemical characteristics that are combined to create a stronger, lighter, or sometimes more flexible product.

One of the best-known composites on the market is reinforced plastic. Today, plastic is used in a pure form in most products, such as in toys and water bottles. However, it can be reinforced with fibers from other materials. This technique makes some of the strongest, lightest, and most versatile composites available.

A common use of composites is to reinforce a purer material with fiber from another pure or a composite one. The manufacturer will often add carbon or graphite fibers to a composite. Carbon fibers are conductive, have a remarkable combination of high modulus and tensile strength, have a very low (slightly negative) CTE (coefficient of thermal expansion), and offer good resistance to high temperatures. These characteristics make carbon an excellent fiber for various businesses, and it fuses easily with multiple materials.

In addition to carbon, fiberglass is a fairly common fiber reinforcement material. Fiberglass is not as strong or rigid as carbon fiber, but it does have specific attributes that make it desirable in many applications. Glass fiber is nonconductive (i.e., an insulator) and is generally invisible for most types of transmissions. This makes it a good choice for electrical or broadcast applications.

Resins are an essential part of composites. They are the matrices that hold the separate materials together without them being completely fused into a single pure material.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top