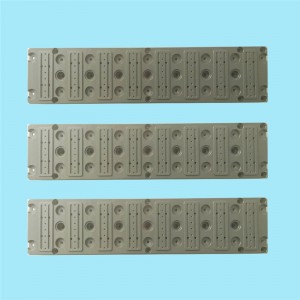

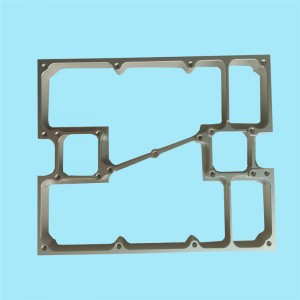

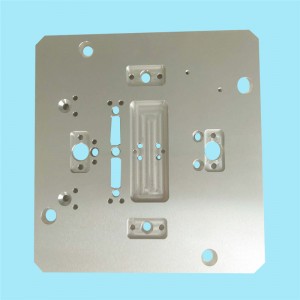

Our CNC Milling for Various Industrial Applications

Turning

Turning is a machining process performed by a lathe; the lathe spins the workpiece as the cutting tools move across it. The cutting tools work along two axes of motion to create cuts with precise depth and width. Lathes are available in two different types, the traditional, manual type, and the automated, CNC type. The turning process can be performed on either the exterior or interior of a material. When performed on the inside, it is known as "boring”—this method is most commonly applied to create tubular components. Another part of the turning process is called "facing” and occurs when the cutting tool moves across the end of the workpiece – it is typically performed during the first and last stages of the turning process. Facing can only be applied if the lathe features a fitted cross-slide. It used to produce a datum on the face of a casting or stock shape that is perpendicular to the rotational axis.

Lathes are generally identified as one of three different sub-types – turret lathes, engine lathes, and special purpose lathes. Engine lathes are the most common type found in use by the general machinist or hobbyist. Turret Lathes and special purpose lathes are more commonly used for applications that require repeated manufacturing of parts. A turret lathe features a tool holder that enables the machine to perform a number of cutting operations in succession without interference from the operator. Special purpose lathes include, for example, disc and drum lathes, which an automotive garage would use to reface the surfaces of brake components.

CNC mill-turning centers combine head and tail stocks of traditional lathes with additional spindle axes to enable the efficient machining of parts that have rotational symmetry (pump impellers, for instance) combined with the milling cutter’s ability to produce complex features. Complex curves can be created by rotating the workpiece through an arc as the milling cutter moves along a separate path, a process known as 5 axis machining.

Drilling/Boring/Reaming

Drilling produces cylindrical holes in solid materials using drill bits—it is one of the most important machining processes as the holes that are created are often intended to aid in assembly. A drill press is often used but bits can be chucked into lathes as well. In most manufacturing operations, drilling is a preliminary step in producing finished holes, ones that are subsequently tapped, reamed, bored, etc. to create threaded holes or to bring hole dimensions within acceptable tolerances. Drill bits will usually cut holes larger than their nominal size and holes that are not necessarily straight or round due to the flexibility of the bit and its tendency to take a path of least resistance. For this reason, drilling is usually specified undersize and followed by another machining operation that takes the hole out to its finished dimension.

Milling

Milling uses rotating cutters to remove material, unlike turning operations where the tool does not spin. Traditional milling machines feature moveable tables on which the workpieces are mounted. On these machines, the cutting tools are stationary and the table moves the material so that the desired cuts can be made. Other types of milling machines feature both table and cutting tools as moveable implements.

Two principal milling operations are slab milling and face milling. Slab milling uses the peripheral edges of the milling cutter to make planar cuts across the surface of a workpiece. Keyways in shafts can be cut using a similar cutter though one that is narrower than the ordinary slab cutter. Face cutters instead use the end of the milling cutter. Special cutters are available for a variety of tasks, such as ball-nose cutters which can be used to mill curved-wall pockets.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top