Products

-

Turning Machining Metal Parts Mounting Ring

OEM Customized Universal Black Mounting Ring Bracket Housing CNC Machining Parts.

P/N: 34623-042-034-004

Material: 16MnCr5,Alloy Steel

Decription: Mounting Ring

Surface Finishing: CNC and Hardening

-

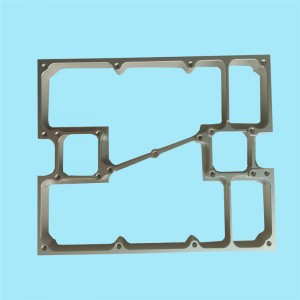

Precision Machined Aluminum Plates – Customized

Product Name: Plate

Material: AlMg4.5Mn-3.3547

Material class: Al-101

Size: Tolerances according to ISO2768-mk

Surface finish: Anodized clear

Weight: 0.534kg

Surface: 43876.361mm²

Volume: 187503.329mm²

Place of Origin: China

Design: According to customer drawing or sample.

Process Type: Stamping, Punching, Laser Cutting, Bending, etc.

Materials Available: Aluminum, Stainless Steel, Carbon Steel, Titanium, Brass, Copper, Alloy, Plastic, etc.

Inspection: According to Customers’ Request.(Self-provided testing machine)

Packing: Suitable Package for long time Transportation.

Lettering: According to customers’ Request.

-

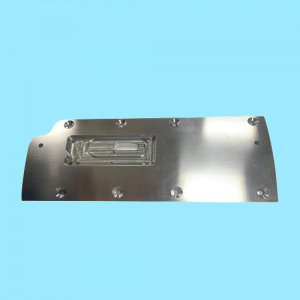

High-Performance Aluminum Interface Plate for Better Results

Product Name: Interface Plate

Material: AL 7075-T73/T735/T651

Size: According to customers’ drawing or sample.

Face Treatment: Oxidation White

Place of Origin: China

Design: According to customers’ drawing or sample.

Process Type: Stamping, Punching, Laser Cutting, Bending, etc.

Inspection: According to Customers’ Request.

Materials Available: Aluminum, Stainless Steel, Carbon Steel, Titanium,

Brass, Copper, Alloy, Plastic, etc.

Packing: Suitable Package for long time Transportation.

Lettering: According to customers’ Request.

-

-

Upper Copper Tab Guide Plate for Smooth Operations

Product Name: Copper Tab Guide Plate, Upper

Material: C15500 Copper or Equivalent

Finish: None

Properties: Tensile strength ultimate: 71 KSI

Hardness: 80 Rockwell B

Place of Origin: China

Design: According to customer drawing or sample.

Process Type: Stamping, Punching, Laser Cutting, Bending, etc.

Inspection: According to Customers’ Request.

Materials Available: Aluminum, Stainless Steel, Carbon Steel, Titanium, Brass, Copper, Alloy, Plastic, etc.

Packing: Suitable Package for long time Transportation.

Lettering: According to customers’ Request.

-

OEM Customized Excellent Quality Iron Supporter

Product Name: Support

Material: 1.2767-X45 NiCrMo 4

Size: Dimensions with tolerances DIN-ISO 2768-1

Face Treatment: Black Oxide (Surface specifications according to DIN ISO 1302)

-

CNC Precision Machined Stainless Steel Parts

What is CNC precision machining and how does it work?

The CNC machining process uses a solid block of material such as brass, copper or steel. Using numerically controlled tools, it accurately and precisely delivers parts to a very high standard. Lathes, mills, routers, and grinders are tools typically found in CNC machinery. The digital template and autonomous machining practically eliminate human error and achieve accuracy within 1/1000th.

The CNC machine is programmed by the operator based on the specifications laid out in the CAD drawings. The programming process generates code which controls the machine to produce the desired finished product. A test run is completed to ensure that there are no errors in the programming. This trial run, called ‘cutting air’ is integral to the machining of top quality finished parts and largely eliminates material wastage and unnecessary downtime. This program can then be used repetitively to create multiple uniform products, all CNC outputs matching the prototype’s exact specifications.

Using CNC machinery is also considerably quicker than conventional machining, providing a cost-effective service with a quick turn-around.

-

CNC Machined Parts based on advanced manufacturing methods

A quick comparison of CNC machine tools

CNC machines are hugely versatile pieces of equipment, in large part thanks to the range of cutting tools they can accommodate. From end mills to thread mills, there’s a tool for every operation, allowing a CNC machine to perform a variety of cuts and incisions in a workpiece.

Cutting tool materials

In order to cut through the solid workpiece, cutting tools must be made from a harder material than the workpiece material. And since CNC machining is regularly used to create parts from very hard materials, this limits the number of available cutting tool materials.

-

Solutions to Produce Complex Parts with Great Tolerances And Dimensional Parameters

Types of CNC Machining

Machining is a manufacturing term encompassing a broad range of technologies and techniques. It can be roughly defined as the process of removing material from a workpiece using power-driven machine tools to shape it into an intended design. Most metal components and parts require some form of machining during the manufacturing process. Other materials, such as plastics, rubbers, and paper goods, are also commonly fabricated through machining processes.

-

Our Materials for CNC Turning Parts

CNC Machining Process

Speaking of the numerical control machining process, it is a manufacturing process which utilizes computerized controls to operate the CNC Machines and cutting tools to get the designed parts with metals, plastics, wood or foam, etc. Although the CNC Machining process offers various operations, the fundamental principles of the process are same. The basic CNC machining process includes:

-

CNC-turned Parts with Final Inspection

METHODS OF PRECISION MACHINING

Precision machining relies on the use of advanced, computerized machine tools to achieve demanding tolerances and create complex geometric cuts with a high degree of repeatability and accuracy. This can be achieved through the use of automated computer numerical control (CNC) machine tools.

-

Highly Professional OEM CNC Machined Parts

What Is an Original Equipment Manufacturer (OEM)?

An original equipment manufacturer (OEM) traditionally is defined as a company whose goods are used as components in the products of another company, which then sells the finished item to users.